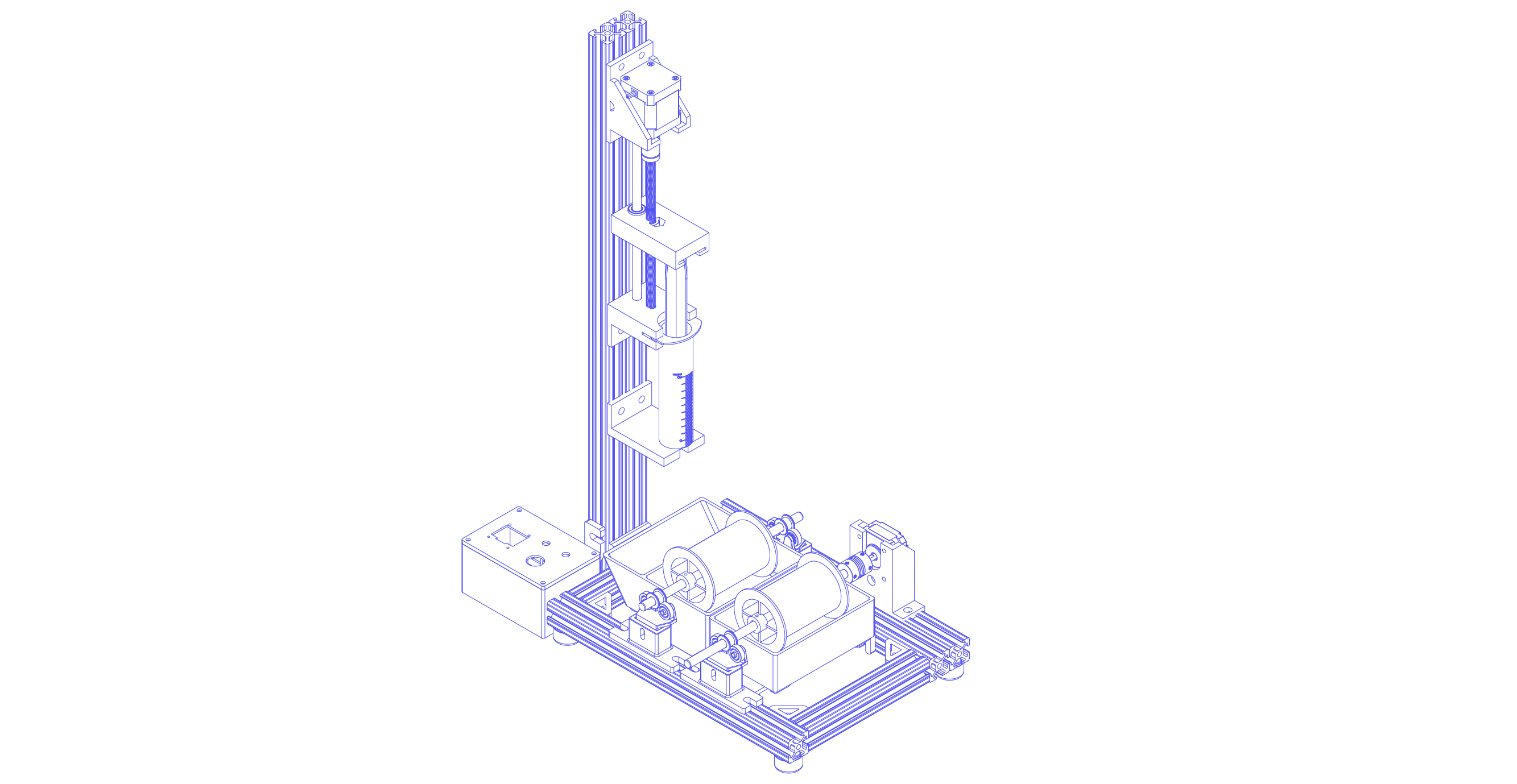

Assembly

Tools Needed

- Needle Nose Pliers

- Screw-driver set

- Allen key set

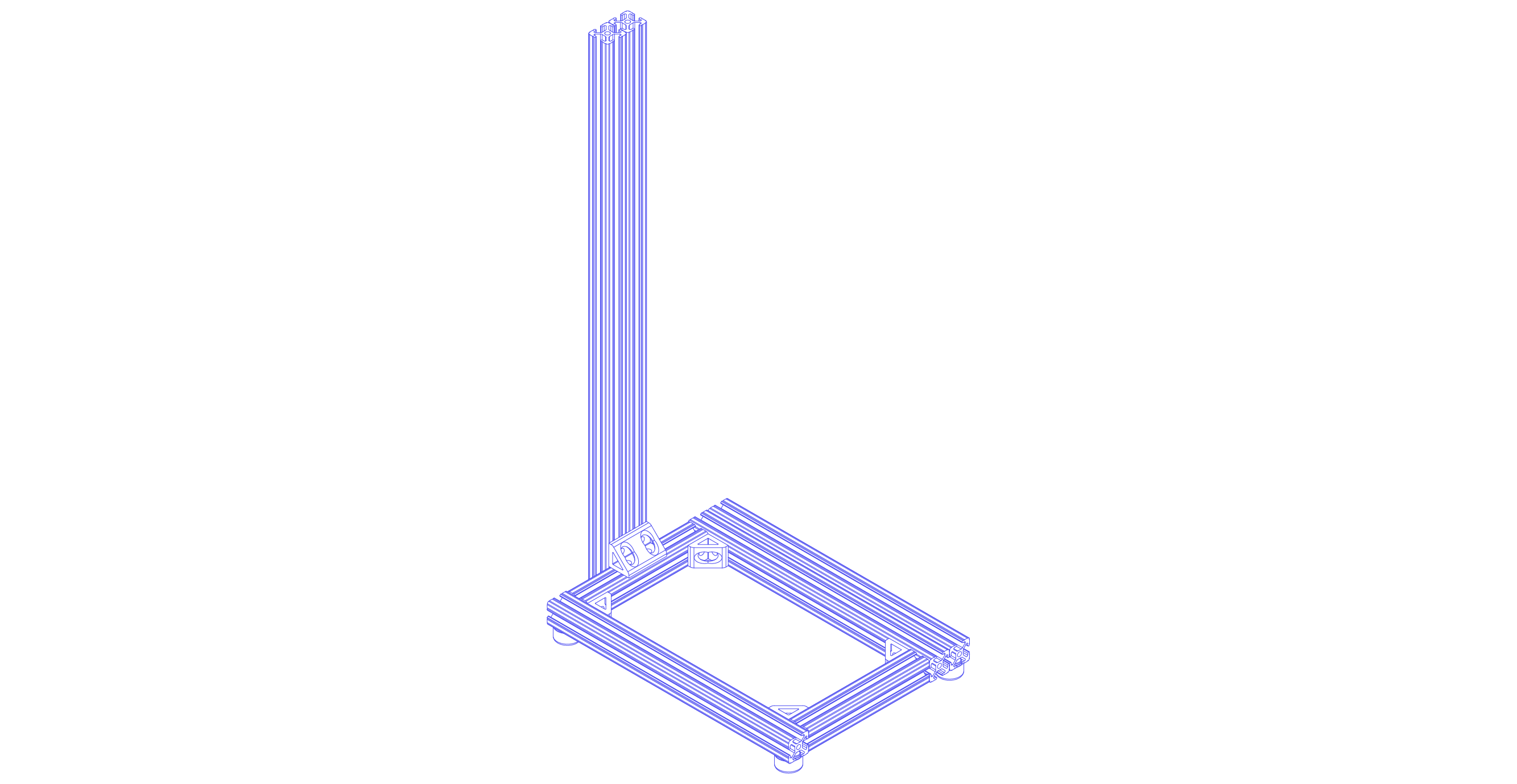

I. Frame

Base Frame

- Place down one

12" single railand one12" double railboth on their 1" x 12" side. - In between the two rail, place two

6" single railon either end so the four rails form a 9" x 12" rectangle. - Prepare Screws for Tank Stands

- Loosely screw together 4 sets of

cap screwsandT-nuts. - Slide 2 assembled screws onto the

12" single railsand 2 onto the12" double rails. - Make sure the screws face the inside of the frame-rectangle.

- Loosely screw together 4 sets of

- Attach the frames together using 8

cap screws, 8T-nuts, and 4single brackets. - Attach a

bumperbelow each corner (4 total).

Vertical Frame

- Orient the rectangular framing such that the

12" double railis on the right. - Behind the farther

6" single rail, center one24" double railoriented vertically with a 2" side flush with the frame. - Attach the

24" double railto the base frame using 4cap screws, 4T-nuts, and adouble bracket.

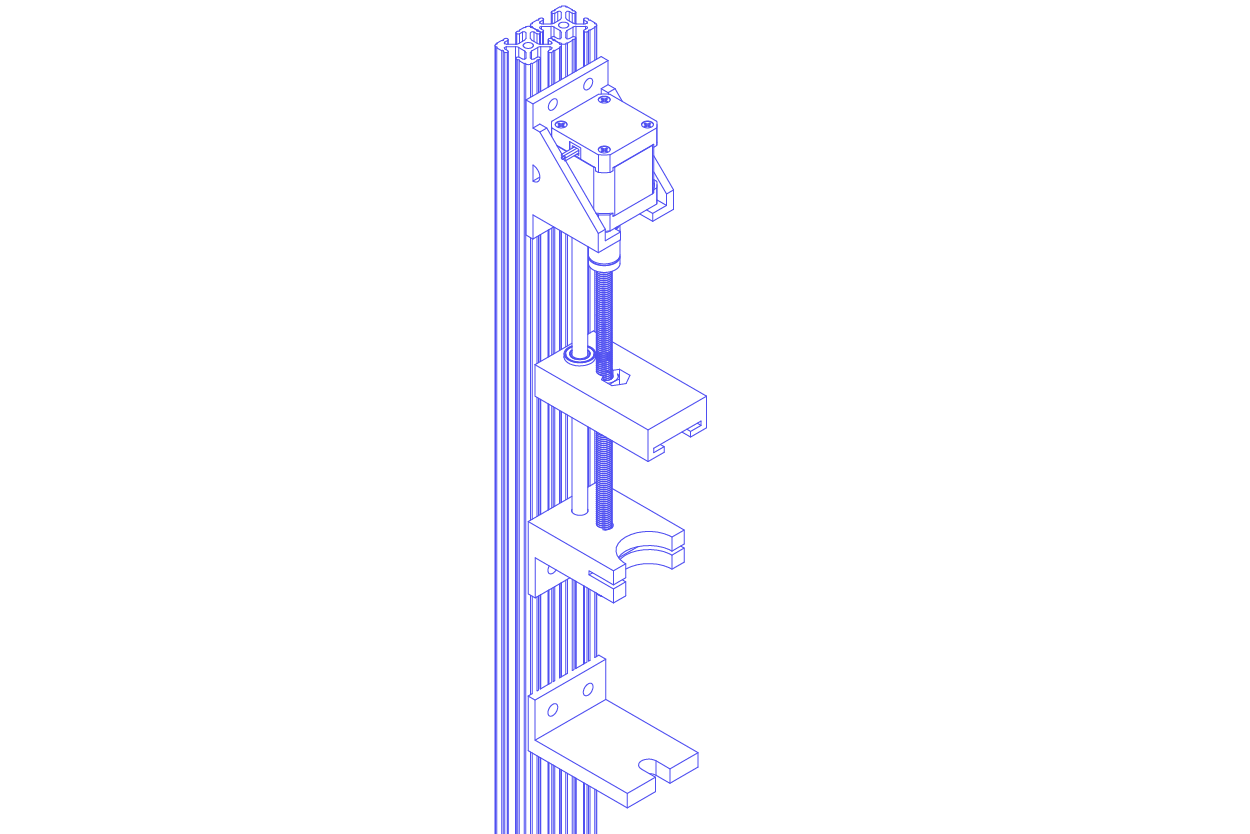

II. Syringe Pump

Syringe Holders

- Attach a

cap screwandT-nutto each screw hole of the 3-D printed syringe pump mechanisms.

When attaching the screws, leave room for the pieces to slide onto the framing.

TheT-nutshould be on the flat side of the print. - Slide the

syringe hub holderonto the24" double railoriented like an “L”. - Tighten the screws when the holder is 5.5" above the rectangular frame.

- Slide the

flange holderonto the24" double railoriented like an upside-down “L”. - Tighten the screws when the

flange holderand thesyringe hub holdercan fit yoursyringe.

Ours is approximately 5.25" apart at their farthest edges.

Syringe Displacer

- Place the

steel hex nutinto thesyringe displacer'shexagonal slot and slide it into place.

The threaded part of thenutshould align with the circular cutout on thedisplacer. - Place the

linear bearinginto thesyringe displacer'scircular hole.

You want the bearing to be flush with the syringe cutout. - Spin the

threaded rodinto thesteel hex nutuntil thesyringe displaceris around the middle of thethreaded rod. - Slide one

motion shaftinto thelinear bearing. - Place the

motion shaftand thethreaded rodinto their corresponding hole in theflange holder.

Themotion shaftis closer to the frame, thethreaded rodis farther.

Syringe Motor

- Attach the 8mm end of the

rigid couplerto the top of thethreaded rodusing twoM4 set screws. - Attach the

syringe motorto thesyringe motor mountusing 4M3 screws. The wire should face left or right. - Slide the

syringe motor mountonto the framing so the motor shaft fits into therigid coupler.

Also, themotion shaftfits intosyringe motor mount'scylindrical extrusion. - Secure the motor to the coupler with 2

M4 set screws. - Tighten the mount’s

cap screws.

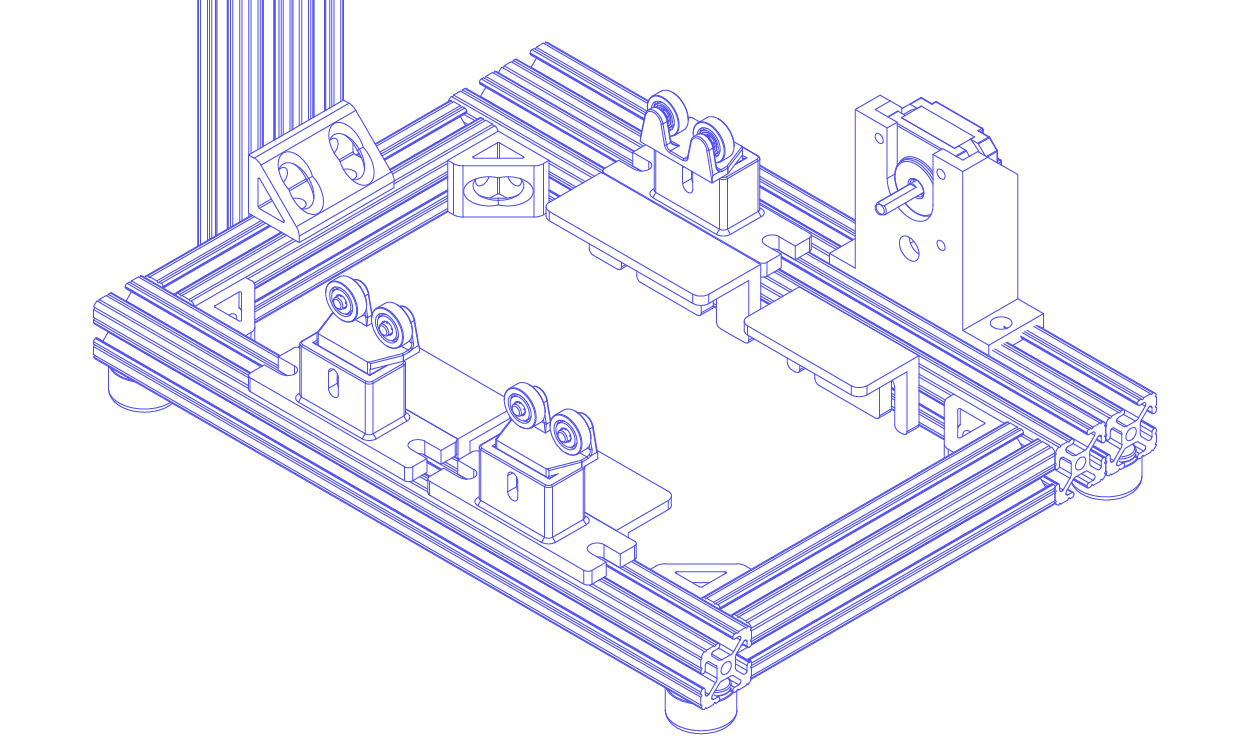

III. Baths

Assemble Rod Posts

- Place a

nylon hex nutinto the 3D printedaxel'shexagonal slot. - Slide the

axelinto apostand secure with anylon screw. - Snap two

plastic ball bearingsonto theaxlewith the bearings facing out. Eventually, you want the metal bearings to be facing away from the baths. - Repeat steps 1-3 two more times (3 assembled rod posts total).

Attach Passive Roller Posts

Note: orient all the rod posts so that the bearings’ metal parts face out.

- Orient the frame so that the

24" double railis furthest from you. - On the

12" single rail, place one assembledpostwith its bottom edge 2.25" from the bottom of the frame. - Repeat step 2 with

12" double rail'sleft rail. - Attach both

poststo theframewith 4cap screwsand 4T-nuts.

Attach Motorized Roller Posts

- On the

12" single rail, place anotherpostwith its top edge 3.25" from the top of the frame. - Attach the

roller motorto the 3D printedroller motor mountwith fourM3 screws. The wire should face down. - On the

12" double rail’s right half, place theroller motor mountwith its bottom edge 2.25" from the bottom of the frame. The wire faces away from the frame. - Attach the

roller motor mountandpostto the frame with 4cap screwsand 4T-nuts.

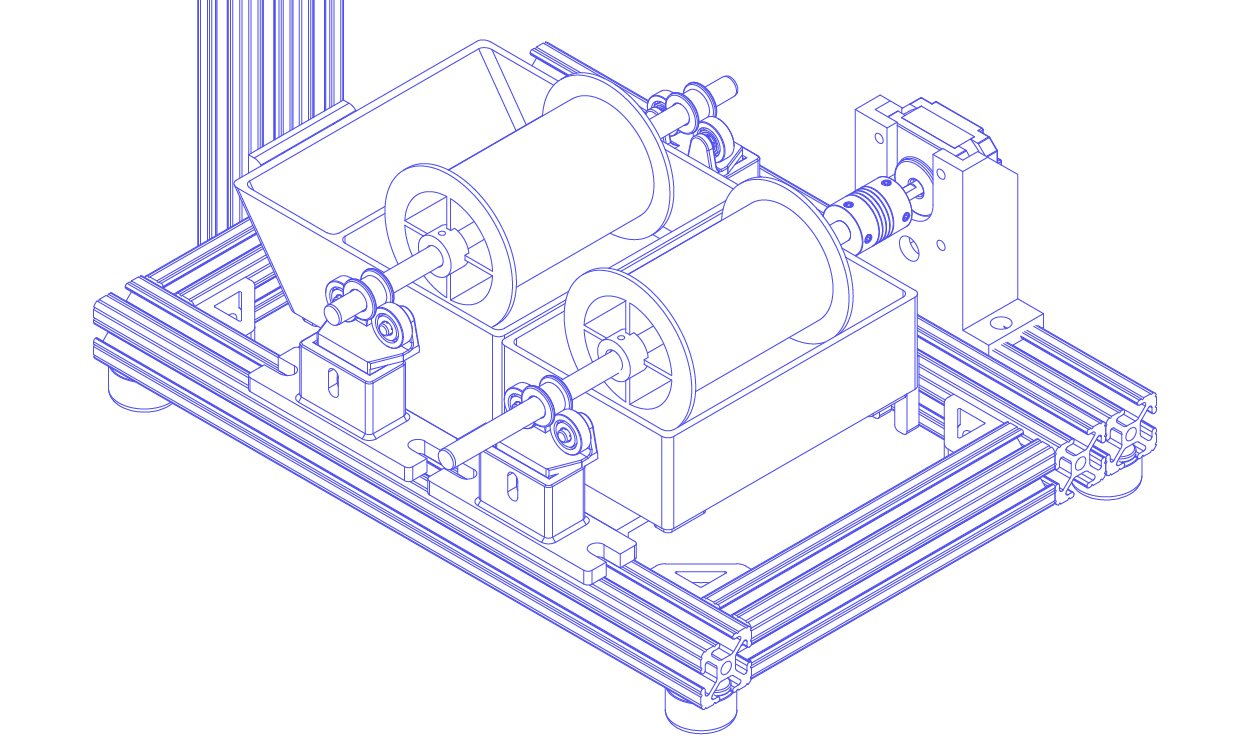

Attach Tanks

Note: tank stands are attached on the inside of the frame in an upside down “L” shape

- Beneath a passive rod

post, attach awide tank standusing the two pre-attached screws farther from you. - Repeat step 1 for the other passive rod

post. - Beneath the motorized rod

post, attach anarrow tank standusing the remaining pre-attached screws. - Repeat step 3 for the

roller motor mount. - Place the

coagulation bathon thewide tank stand. - Place the

wash bathon thenarrow tank stand.

IV. Collectors

Assemble Passive Roller

- Slide one

rolleronto onemotion shaft. - Slide a

shaft sleeveon either side of theroller. - Place the

rolleronto the passive rod posts, aligning theshaft sleeveswith theplastic ball bearings.

Assemble Motorized Roller

- Slide the second

rolleronto the othermotion shaft. - Slide a

shaft sleeveon only one end of themotion shaft. - On the other end, attach the 8mm side of the

flexible couplerusing twoM4 set screws. - Attach the 5mm end of the

flexible couplerto theroller motorusing twoM4 set screws. - Align the

shaft sleevewith theplastic ball bearingson the other side.

Secure Rollers

- Position the

rollersin the middle of the tanks. - Slide an

M2 nutinto each slot of each roller. - Secure the

rollersto themotion shaftswithM2 screws(4 nuts and 4 screws total).

V. Controller Box

Attach PCB

- Place the prepared PCB inside the 3D printed

controller box, ensure the connectors match the outlets on the box. - Secure the PCB with 4

M3 screws.

Assemble Controller Panel

- Remove the threaded ring from the

pushbutton, insert thepushbuttoninto the dedicated slot on the controller top panel. - Secure the

pushbuttonwith the threaded ring. - Remove the nut from the

potentiometer, insert thepotentiometerinto the dedicated slot on the controller top panel. - Secure the

potentiometerwith the nut using a plier. - Place the

displayinto the dedicated slot on the controller top panel. - Secure the

displaywith 4M2 screwswith nuts.

Connecting Wires

- Plug the

pushbutton cableinto theBTN_DIRconnector on the PCB. - Plug the

potentiometer cableinto thePOT1connector on the PCB. - Plug the

display cableinto theOLEDconnector on the PCB. - Plug the

pedal cableinto thePEDALconnector on the PCB

Close the Controller Panel

- Use 4

M2 screwsto attach thecontroller panelonto the controller box

VI. Assemble Full System

Last updated on