Machine Usage Guide

Machine Usage Guide

This guide will walk you through the process of using the Open Wet Spinning machine to create functional threads.

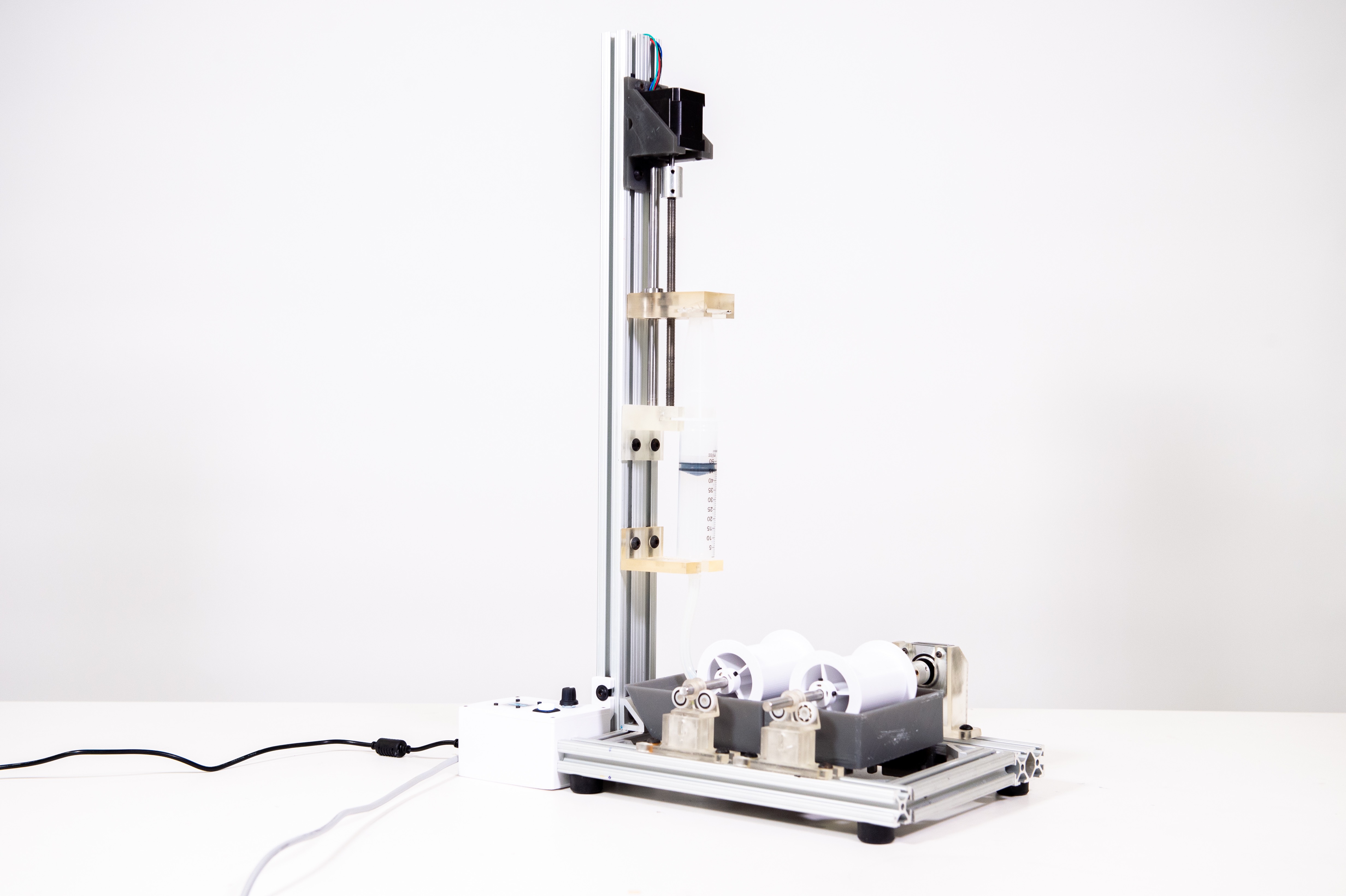

Machine Overview

The wet spinning machine consists of three sub-systems: the syringe pump, the bath and collection system, and the controller box. All the components in these systems are either 3D printed with desktop 3D printers or purchased through general mechanical or electrical component vendors. The three subsystems can be easily disassembled and reassembled to host workshops at different locations. With simple edits, the volume of the syringe pump can be replaced with smaller ones for low-volume sampling. The slotted frame structure can be extended to add more tanks for coating or multiple wash bathes.

Subsystem - Syringe Pump:

- Stepper Motor

- Plunger Displacer

- Syringe Holder

Subsystem - Bath & Collector:

- Coagulation Bath

- Wash Bath

- Passive Roller

- Motorized Roller

- Submerged Needle Dispenser

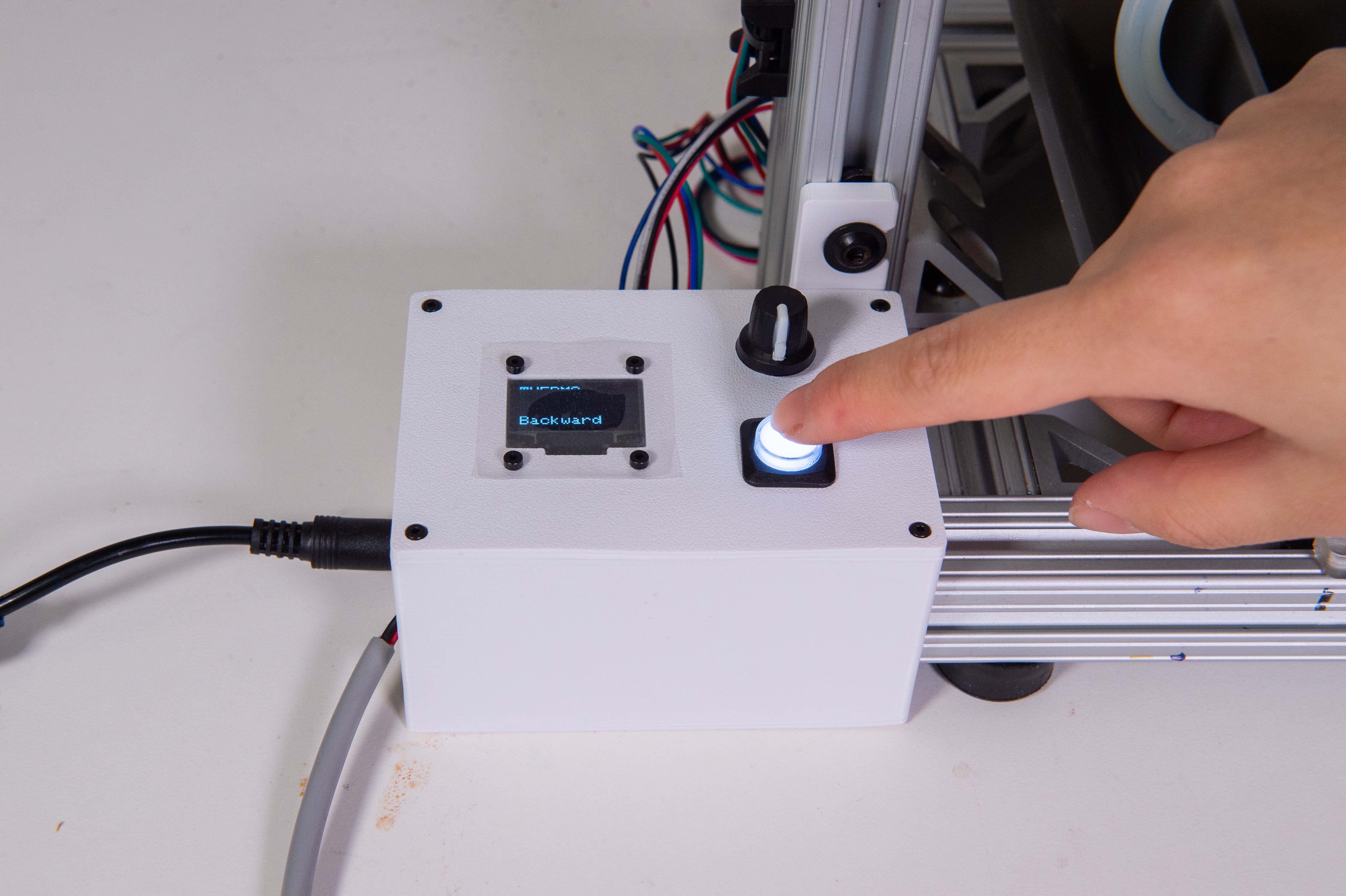

Subsystem - Controller:

- Display

- Speed Selection Knob

- Direction Selection Button

Step-by-Step Instructions

1. Machine Preparation

- Fill the coagulation bath with

10% calcium chloridesolution - Fill the wash bath with

distilled water - Adjust the

syringe displacerto the suitable height for yoursyringe - Load the

syringeonto thesyringe holder - Insert the

syringe plungerinto thesyringe displacer

2. Speed and Direction Settings

- Start with

Resetspeed setting using thepotentiometer - Once ready to spin, switch to

Regular/Thermo/Charcoalspeed setting - Press the

pushbuttonto start themotorized roller

3. Extrusion Process

- Step on the

foot pedalto begin extrusion - Hold the

gauge tipin the air until the first blob forms - Carefully insert the

gauge tipinto thecoagulation bath

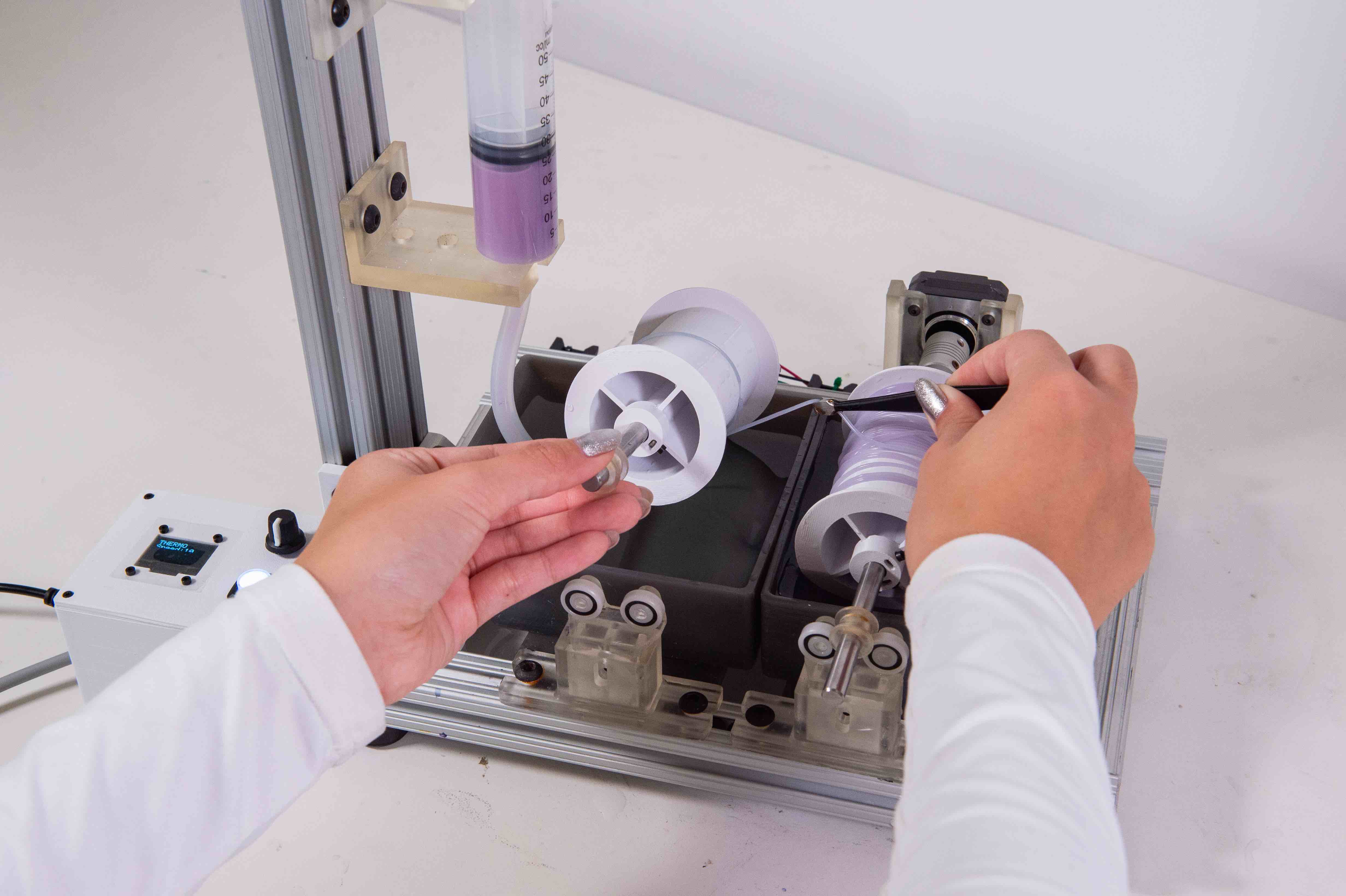

4. Yarn Collection

- Wait for the thread to form in the

coagulation bath - Gently pick up the yarn using tweezers or a collection tool

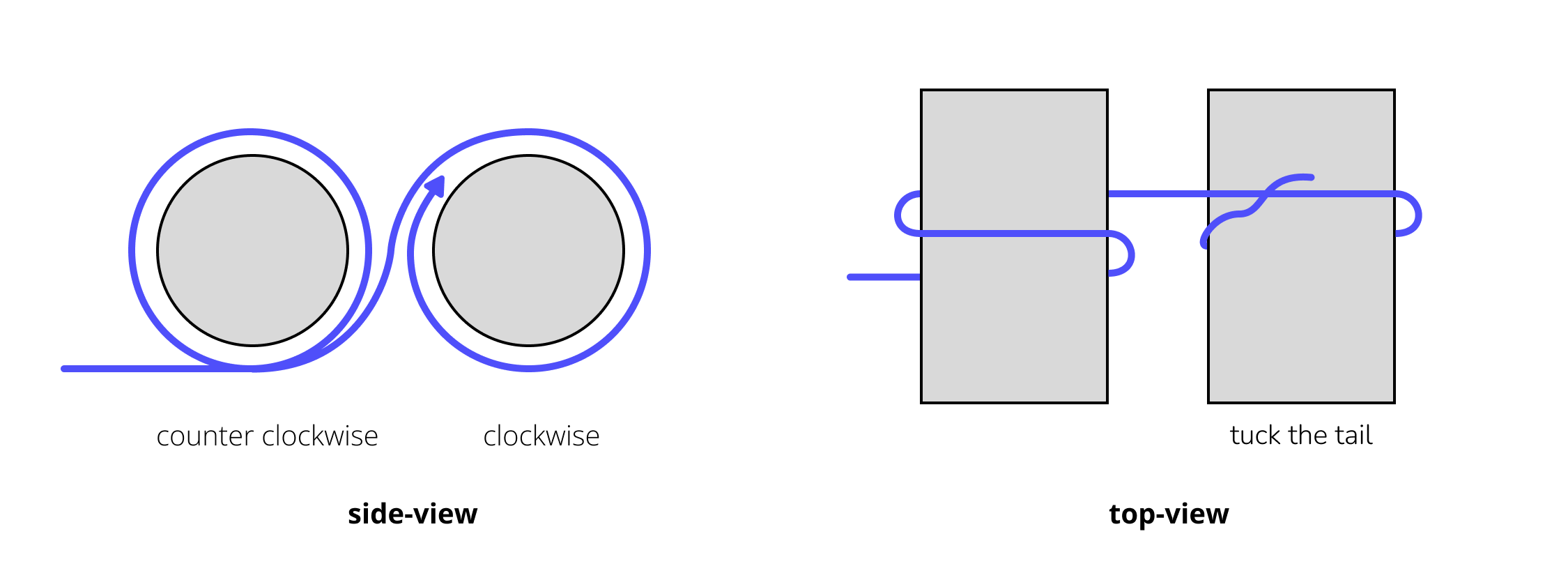

- Wind the yarn around the

passive rollerin thecoagulation bath - Guide the yarn to the

motorized rollerin thewash bath - Ensure proper tension while winding

5. Drying and Storage

- After collecting desired length, carefully remove the thread from the rollers

- Hang the yarns to dry at room temperature

- Allow 4-8 hours for complete drying

- Store in appropriate conditions once dry

Troubleshooting

- If motors aren’t spinning properly, double check that all the

set screwson thecouplersare tight - Sometimes the motors won’t work properly if the

potentiometerknob is between settings. - If the

gauge tipgets coated withcalcium chloridebefore you start extruding, it can clog the syringe. - If the yarn breaks in the middle of spinning, simply pick up the new end and wrap it around the

rollersagain.

Tips for Success

- Clean the machine thoroughly after each use

- Maintain consistent room temperature during spinning

- Keep detailed records of your settings and results

- Practice with basic solutions before moving to more complex materials

Next Steps

- Check our recipes section for different material combinations

- View the assembly guide to learn how to assemble the machine

Last updated on